This page is under construction as of May 2021, thus it is incomplete, please come back to learn the full story in a bit.

Years of doing Rover K heads, seeing the damage caused by overheating of the alloy, often even with people taking care, looking after their pride & joy. Then there are the multiple tens of thousands totally trashed, especially sport model cars.

So what did I gleen from looking at the dismantled engines, listening to others investigations and the ideas on faults/fixes, and even the bull spouted by so called experts & now embedded upon the net that people think its true. Like the 'elastomer' seal is to blame, the plastic blok dowels are to blame, the long bolts that hold the head on are to blame and various other 'things'.

I will put forward what I understand & can see, you think it over & decide if it makes sense & I hope benefit from the knowledge.

Firstly as I was told by a Rover tech engineer, as the engine was being designed in the 80's rover was looking to the future & wanting to show off it could produce an efficient & emisions friendly unit unlike all the carburated & somewhat inefficient vehicles populating the roads of the world at the time.

With this in mind the cooling system is built to RAPIDLY heat up & come off Choke/enrichment for the lady in her metro doing 1 or 2 miles or less to the shops as so many trips we make are like. Thus it consumes less fuel making it fuel efficient getting off enrichment, and secondly cleaner emisions, win win.

So this is great until you put it in a sportier model vehicle or 4 by 4 type where the owners are used to just jumping in, turning key and driving off at speed without allowing a warmup & the stat to begin working. So the 'rapid warmup' now turns into 'Rapid fryup', the owners have just ruined their cylinderheads & the nightmare of repeated fails begins- aided by another fault of the design, the headgaskets 'firering'.

So i shall go into my thoughts, backed up with pictures that should help you 'see'. The trouble is where to start- i'll go with flow in the cold engine. The stat is closed, to open it we need heated coolant flowing over the wax portion, this comes via a takeoff from the water outlet branch on back of head- exh side cyl 4.

A pipe assembly takes the coolant to the plastic stat housing under the inlet manifold at front of engine.

The pipes one sees are fairly large Diameter, so one might think there is decent flow.

So we begin to see an engine with 4 cylinders on fast idle around 900rpm with searing combustion gases at around 420C/788F heating the chamber, then flowing around & heating the exh valves/seats which then pass their heat to the head alloy, with finally the gases heating the head alloy while passing through the exh ports to be expelled into the exh manifold. This heat is dealt with by engine coolant in the water jacket in contact with the head alloy & absorbing it, the coolant passing through the stat housing has just enough flow through the engine to move the warming coolant so more cold coolant can absorb more heat & thus keep the alloy at stable levels.

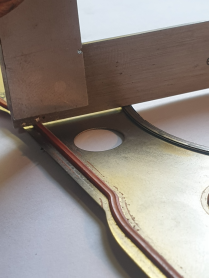

So here we have the elastomer original headgasket design, quality made Stainless steel/inox core which removes all the known possibilities of giving trouble & failing from chemical attack or rusting away as many other gaskets do!!!!

rover got may aspects of the engine spot on, and this simple stainless core one of those perfect aspects.

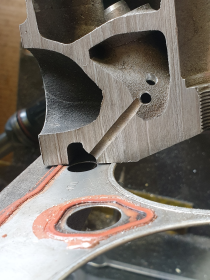

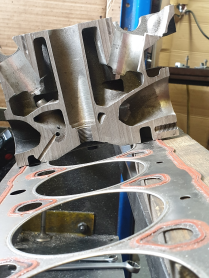

In this photo of a sectioned head cut right through the centre of exh port you can see the coolant transfer passage in gasket feeding directly into the larger coolant channel of head casting.

To the left/right of the transfer passage in gasket one can see the ultra thin space of the coolant boundary layer which is really not in the main flow movement I would say, certainly not with the stat closed and one 13mm hole in the stat casing supplying a whole engine with coolant movement.

This- if I am correct- is also when the whole system is 'not up to pressure', so coolant can boil at 100c as normal. A pressure cap adds 1.5C per lb of cap pressure to the boiling point- thus a 12lb cap raises boiling point to 118C etc

Ok, so this part is what I believe happens to damage the head strength- soften it by excess heat- based on the above previous text details. We have almost no coolant movement in the hottest portion of engine, the exh ports area where its most needed when cold, we also have not raised the coolant boiling point as the coolant is not expanding from gradual heating up all the fluid in conjunction with the pressure cap.

So as I imagine it, like an aluminium pot on an electric element or over a flame- much as the port with combustion gasses the heat source- The casting is rapidly getting very hot & this heat is getting to our ultra thin boundary layer of coolant, now if you allow your engine to idle, the limited coolant flow is adequate to match the heat buildup BUT if you just fire up the vehicle, drive off like a hoon looking to break the sound barrier, I believe the boundary layer begins to boil just as we can see in a pot- try putting a very shallow layer of water in your pot, see how quick it boils!!!! In fact I must try using a flat based glass cooking dish inside a pot to recreate the boundary layer & see the effect???? try It and let me know!!!

So if our boundary layer is boiling up its obviously no longer adequetely removing the heat in the alloy & thus the cycle worsens, we have a 70mm + length of our gasket 'firering' trying to seal against the overheating alloy under extreme clamping loads from the headbolts, slowly as the alloy 'gives/loses' structural integrity under the excess heat, the gasket begins to indent the head. This loosening of grip on the firering then allows firering movement at the head & frittering- you can see this as a grey line in the alloy.

Sorry, I am finally upgrading my site starting May 2021, this page is a new addition & is yet to be filled, come back in a while & hopefully its completed